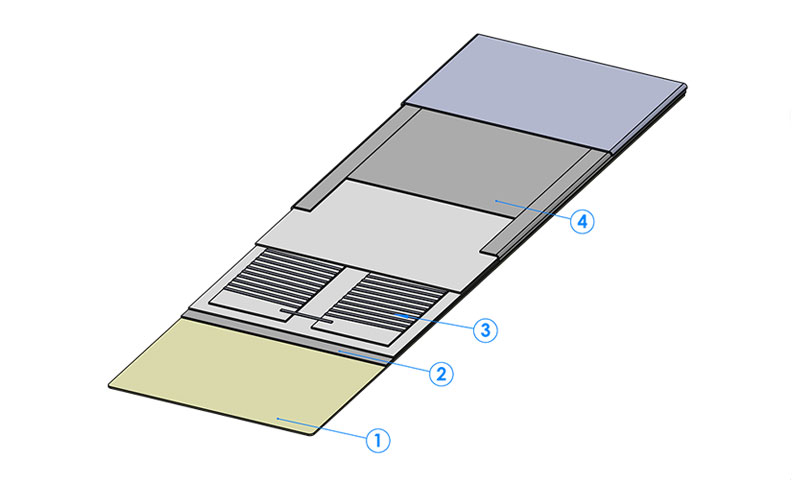

GM.52 Integrated heat transfer plate, 1.5 mm thickness, recommended for heaters with numerous holes to ensure more uniform heat distribution.

1. Heat transfer plate

2. Sheet metal plate

3. Insulation sandwich with ressistance wire

4. Sheet metal cover plate

|

|

Isolation material:

|

Micanite

|

Operating temperature:

|

Up to 350°C

|

Diameter:

|

From 30 mm

|

Sheath material:

|

Stainles steel AISI430

|

Width:

|

20 to 800 mm

|

Sheath material:

|

Nickel-Chrom 80/20

|

Max Watt densty:

|

4 W/cmm2

|

Heating conductor:

|

Temp. resistant cable with steel mesh up to 400°C

|

Voltages:

|

230, 400V or other

|

For elements with a diameter above 400 mm we recommend using more heating segments. For elements with a diameter above 400 mm we recommend using more heating segments. |

|

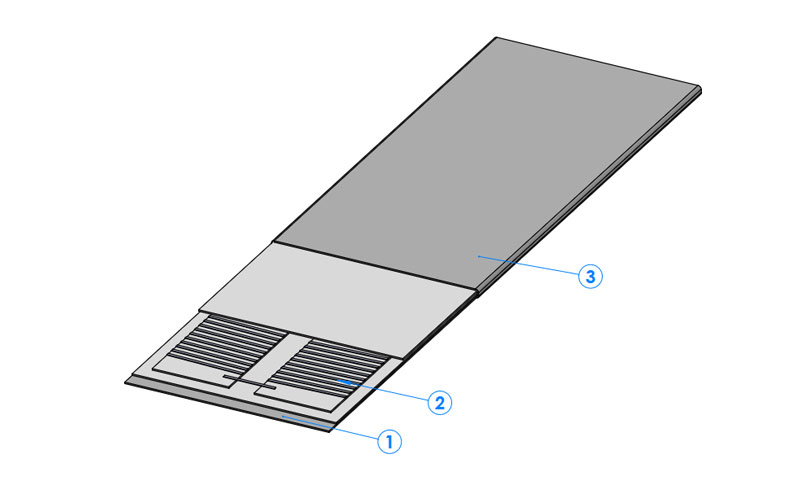

Inside-out heating element

1. Sheet metal cover plate

2. Insulation sandwich with ressistance wire

3. Inner sheet metal plate

|

|

Isolation material:

|

Micanite

|

Operating temperature:

|

Up to 350°C

|

Diameter:

|

From 30 mm

|

Sheath material:

|

Stainles steel AISI430

|

Width:

|

20 to 800 mm

|

Sheath material:

|

Nickel-Chrom 80/20

|

Max Watt densty:

|

4 W/cmm2

|

Heating conductor:

|

Temp. resistant cable with steel mesh up to 400°C

|

Voltages:

|

230, 400V or other

|

Clamping:

|

standard, wedge closing, cam lock

|

| |

For elements with a diameter above 400 mm we recommend using more heating segments. For elements with a diameter above 400 mm we recommend using more heating segments. |

|

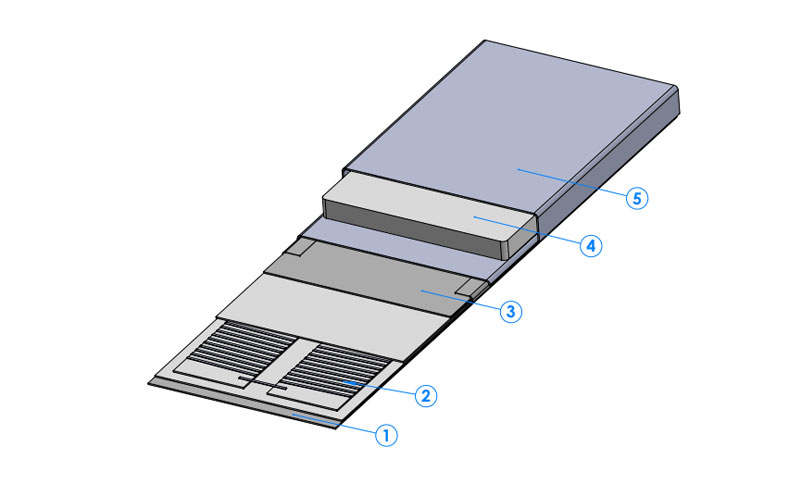

Heating element with sheet metal cover and insulation

1. Bottom sheet metal plate

2. Insulation sandwich with resistance wire

3. Sheet metal cover plate

4. Option with or without insulation d=10mm

5. Outside sheet metal cover

|

|

Isolation material:

|

Micanite

|

Operating temperature:

|

Up to 350°C

|

Diameter:

|

From 30 mm

|

Sheath material:

|

Stainles steel AISI430

|

Width:

|

20 to 800 mm

|

Sheath material:

|

Nickel-Chrom 80/20

|

Max Watt densty:

|

4 W/cmm2

|

Heating conductor:

|

Temp. resistant cable with steel mesh up to 400°C

|

Voltages:

|

230, 400V or other

|

Outside insulation

|

option with 10 mm integrated insualtion.

|

| |

For elements with a diameter above 400 mm we recommend using more heating segments. For elements with a diameter above 400 mm we recommend using more heating segments. |

|