INFORMATIONS

|

|

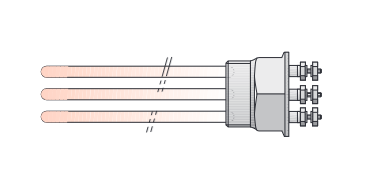

Standard Voltage:

|

230V, 400V

|

Thread:

|

G 1 1/2

|

Sheath material:

|

Stainles steel 1.4435 (AISI316 L)

|

Protection cap:

|

YES ( IP41, IP64)

|

Max Watt densty:

|

9 W/cmm2

|

Thermostat:

|

As option

|

Heating conductor:

|

Nickel-Chrom 80/20

|

Limitor:

|

As option

|

|

| EHK standard dimensions |

| Articel Nr. |

Immersion lenght (mm) |

Power for 230V (W) |

Surface load (W/cm2) |

| 105190 |

170 |

750 |

2 - 3 |

| 105191 |

240 |

1000 |

| 105192 |

480 |

1500 |

| 105193 |

600 |

2000 |

| 105194 |

880 |

3000 |

| 105195 |

170 |

1000 |

4 - 5 |

| 105196 |

240 |

1500 |

| 105197 |

480 |

3000 |

| 105198 |

600 |

4500 |

| 105199 |

880 |

6000 |

| 105200 |

170 |

2500 |

8 - 9 |

| 105201 |

240 |

3000 |

| 105202 |

480 |

6000 |

| 105203 |

600 |

7500 |

| 105204 |

880 |

10000 |

| Description |

Code |

| Protection IP 41 |

Whitout thermostat |

120800 |

| With thermostat |

120801 |

| With limitor |

120802 |

| Protection IP 64 |

Whitout thermostat |

120803 |

| With thermostat |

120804 |

| With limitor |

120805 |

| Thermostat |

| Single-phase 30 - 110°C |

120810 |

| Single-phase 50 - 300°C |

120811 |

| 3-phase 30 - 110°C |

120812 |

| 3-phase 50 - 300°C |

120813 |

| Single-phase 0 - 100°C adjustable inside |

120815 |

| Single-phase 50 - 320°C adjustable inside |

120816 |

| 3-phase 50 - 300°C adjustable inside |

120817 |

| Limitor single-phase 0 - 100°C |

120819 |

| Limitor single-phase 70 - 300°C |

120814 |

| Fixation elements and seals |

| Hexagonal nut G1 1/2 SW 60 Brass |

600157 |

| Hexagonal nut G1 1/2 SW 60 Chrome steel |

600158 |

| Copper mineral gasket 48x54x2 mm |

600431 |

The assembly of the heater can be made onto a container with a wall thickness of at least 10 mm by a threaded hole G 1 1⁄2. The hole needs to be chamfered 2.5 x 45° on the assembly side so that the nipple can easily be mounted. For the assembly onto containers with a wall thickness less than 10 mm it is necessary to use G1 1⁄2 nut. Counter nut or seal can be supplied separately.

|

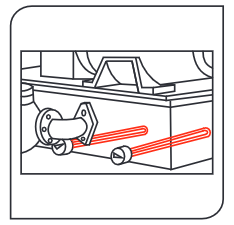

Preheating of oil to ensure efficient lubrication |

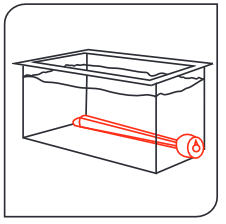

Prepairing hot water |

|

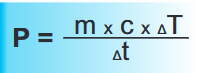

The power required to heat the mass of a medium is calculated as follows:

|

Calculation formula

P = power in Watt

m = mass in kg

c = specific heat in Wh/kg K

ΔT = temperature difference in Kelvin

Δt = heating up time in hours

In applications with high material flow, the power should be calculated by using the mass per hour, in kg/h instead of the mass and heating up time. Material properties for the calculation see bottom of the page |

|

Heat losses

To compensate heat losses, the power should be increased by:

for non-insulated containers 20% to 30%

for insulated containers 10% to 20%

Heat losses for open containers by vaporization

Water temperature Loss per m2 of water surface in kW/h

40˚C 0,6

60˚C 2,8

80˚C 7,0

95˚C 15,0

|

For the melting or the vaporization of a medium the melting or vaporization heat in Wh/kg has to be added to the calculation indicated beside. By using equipment with a thermostat, the power of the heater may be two times higher than calculated.

| Substances |

Density kg/dm3 |

Melting temp. Wh/kg K |

Melting temp. °K |

Melting heat Wh/kg |

Boiling point °K |

Vaporization Heat Wh/kg |

| Water |

1 |

1,162 |

273 |

92,66 |

373 |

626,66 |

| Air |

0,0013 |

0,279 |

53 |

- |

82 |

- |

| Parafin |

0,9 |

0,908 |

325 |

- |

573 |

- |

| Heating oil |

0,83 |

0,58 |

263 |

- |

~450 |

~160 |

| Alcohol |

0,77 |

1,163 |

195 |

27,9 |

240 |

380,17 |

|

|