TECHNICAL SPECIFICATIONS

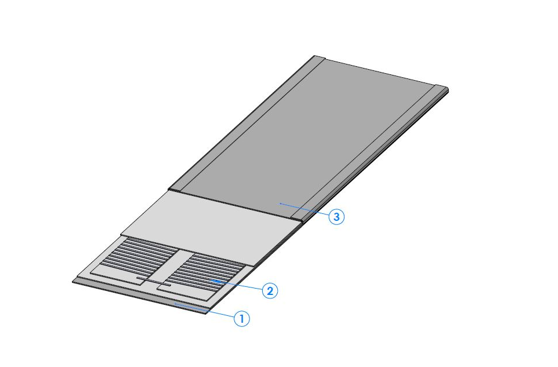

- Sheet metal plate

- Insulation sandwich with resistance wire

- Sheet metal cover

|

|

Standard Voltage:

|

230V, 400V (other on request)

|

Wall thickness:

|

4 mm

|

Sheath material:

|

AISI 0430 / Aluminized steel

|

Width:

|

20-1200 mm

|

Isolation material:

|

Micanite

|

Lenght:

|

20-1500 mm

|

Max Watt densty:

|

4 W/cmm2

|

Connection:

|

Variety of options, see bottom

|

Operating temperature:

|

max 350°C, for higher temp. we use GM.65

|

Connection cable:

|

Temp. resistant cable with steel mesh up to 400°C

|

Heating conductor:

|

Nickel-Chrom 80/20

|

Integrated thermocouple:

|

Type: J, K, PT100

|

|

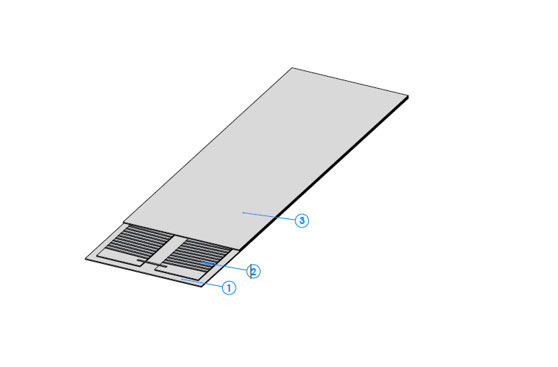

- Bottom insualtion MICA

- MICA with resistance wire

- Top insulation MICA

|

|

Standard Voltage:

|

230V, 400V (other on request)

|

Wall thickness:

|

2,5 mm

|

Sheath material:

|

no

|

Width:

|

20-1200 mm

|

Isolation material:

|

Micanite

|

Lenght:

|

20-1500 mm

|

Max Watt densty:

|

4 W/cmm2

|

Connection:

|

Only wires

|

Operating temperature:

|

max 350°C, for higher temp. we use GM.65

|

Connection cable:

|

Temp. resistant cable with steel mesh up to 400°C

|

Heating conductor:

|

Nickel-Chrom 80/20

|

Integrated thermocouple:

|

Type: J, K, PT100

|

|

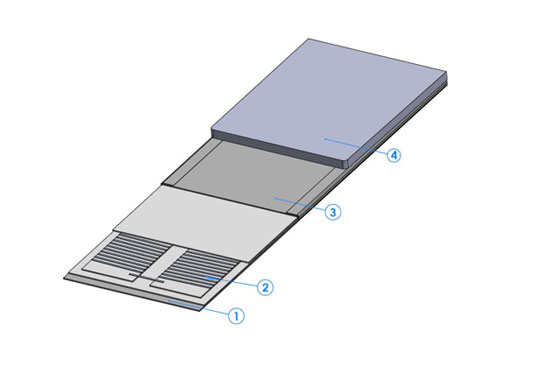

- Sheet metal plate

- Insulation sandwich with resistance wire

- Sheet metal cover

- Pressure plate ( Fe, AISI 0304)

|

|

Standard Voltage:

|

230V, 400V (other on request)

|

Wall thickness:

|

4 mm + (3,4,5,6,8,10 mm)

|

Sheath material:

|

AISI 0430 / Aluminized steel

|

Width:

|

20-1200 mm

|

Isolation material:

|

Micanite

|

Lenght:

|

20-1500 mm

|

Max Watt densty:

|

4 W/cmm2

|

Connection:

|

Variety of options, see bottom

|

Operating temperature:

|

max 350°C, for higher temp. we use GM.65

|

Connection cable:

|

Temp. resistant cable with steel mesh up to 400°C

|

Heating conductor:

|

Nickel-Chrom 80/20

|

Integrated thermocouple:

|

Type: J, K, PT100

|

|

|